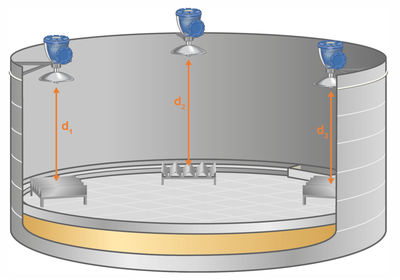

Specifically engineered for floating roof storage tanks the model 715 with 48z lead weight configuration offers a safe non invasive and reliable level solution for storage terminals of crude oil and other materials.

Level switch floating roof tank.

Empty and fill your tank with a single device these dual level switches include two float switches that actuate at different levels.

Some of the ways they react are to.

Dual level vertical mount floatswitches for fuels and oils.

The tanks would be mainly storing gasoline although some may be operating with other fuel like ethanol or diesel during the installation of the level switch 6m to 19m diameter 7m to 17m height.

Warn of high or low level conditions start or stop pumps open or close.

Liquid level sensors or float switches are used to monitor liquid levels in tanks or other vessels and are designed to react according to predefined high or low levels.

Mount through a threaded connection at the top of your tank.

Consult factory for other options.

The level probe sensing element is field adjustable for lengths up to 15 4 6 m.

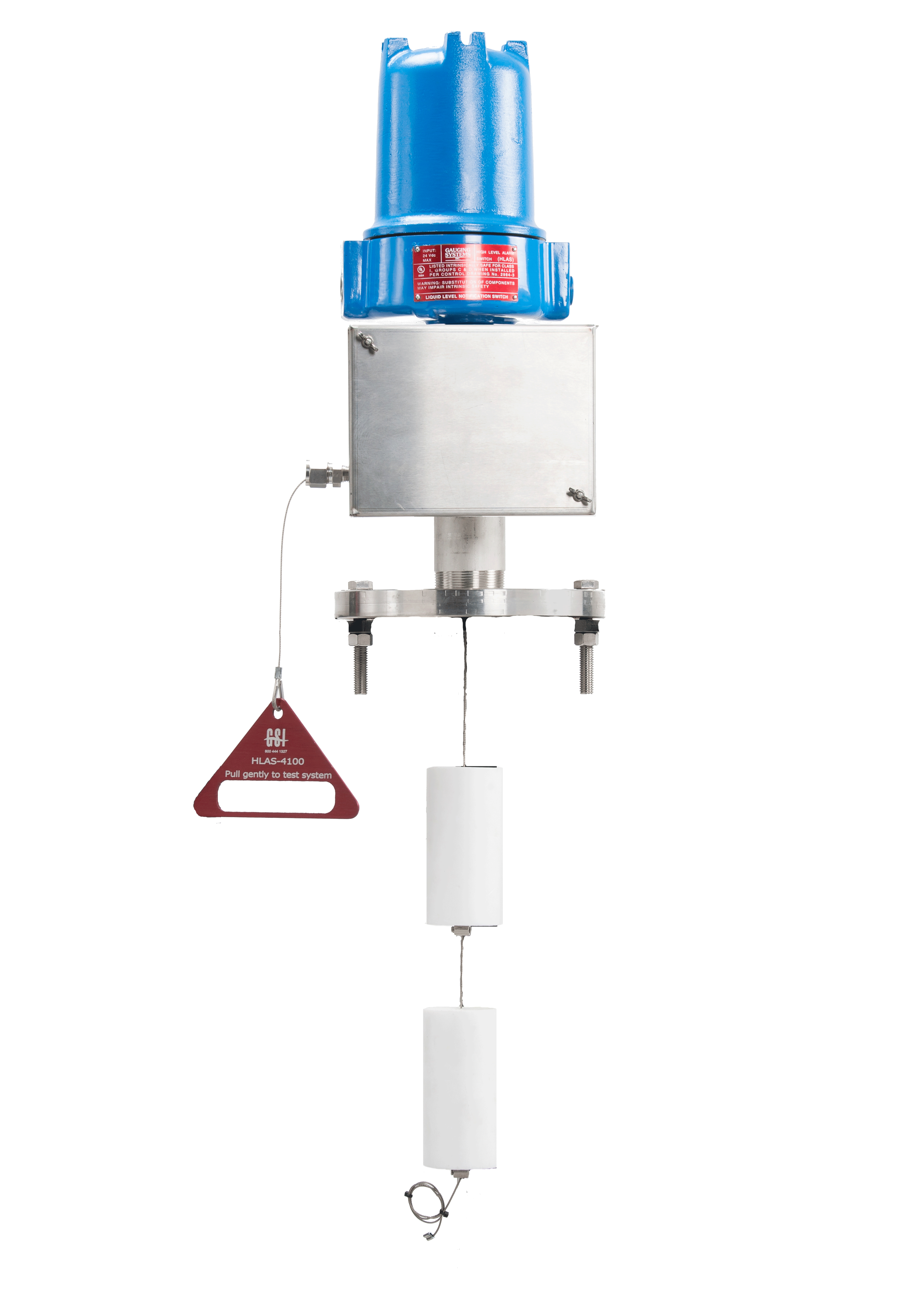

The sil intellipointcapacitance probe level switch is specifically designed for floating roof top tanks internal and external roofs with a flexible brass level sensing probe.

Utilizing a lead weight instead of a float or displacer the roof tank lifts the weight as the level rises triggering an alarm switch warning operators of the potential overflow.

A hollow brass displacer is required if the control is to actuate in liquid as well as by the barrier.

One of my clients asked me if i knew any method to install a level switch for overfill protection in vertical atmospheric tanks with internal floating roofs while the tank is in operation.

Floating rooftop controls the floating rooftop control is designed for installation on barrier floating roof tanks.

Delta controls model 715 48z.